-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Lifting Slings and Components

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- General Industrial Lifting Equipment/

- Lifting Slings and Components /

- Chain Sling Assemblies & Components/

- Lifting Chain Slings/

- Lifting Chain Sling, Grade 12

Lifting Chain Sling, Grade 12

Grade 12 (120) chain slings assembly, 8mm to 16mm and WLL up to 25.6 tonnes. Lighter WLL to weight ratio than grade 8 and grade 10.

CS12-4784

Grade 12 / 120 Lifting chain sling assemblies. Manufactured in Austria, and tailored to meet the growing global demand for top-quality lifting equipment.

Single Leg Chains, 2 Leg Chains, 3 Leg and 4 Leg Chain slings at any length to suit your application with an optional in-line shortening clutch fitted for leg length adjustment.

As well as grade 12 chain slings, we also offer grade 8, grade 10, grade 6 stainless steel or even dyneema (synthetic) chain sling variants that in some instances can be more cost-effective or beneficial due to other features or requirements - harsher environments for example.

Advantages

- High wear resistance due to increased hardness.

- Traceability: appropriate marking on chains & components.

- 50% higher load capacity compared to Grade 8/80.

- 20% higher load capacity compared to Grade 10/100.

- Safety factor 4:1.

- Use of high-grade steels and alloys.

- Production on specially developed bending and welding machines in Europe.

- Process controlled heat and surface procedures.

- BG approved – H29 Number.

- Continuous quality control (ISO 9001, 9002) ongoing research and development of the product.

- Temperature range: -40° to 200°C

Load Chart

| Number of Legs | 1 Leg | 1 Leg | 2 Leg | 2 Leg | 3 and 4 Leg | |||

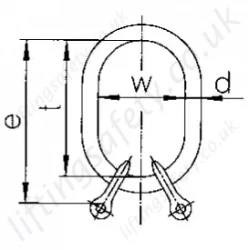

| Image Example |

|

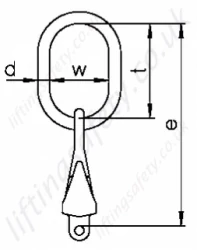

|

|

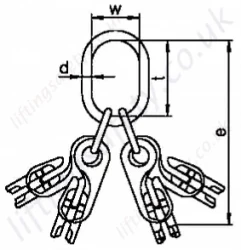

|

|

|||

| Angle of Inclination | - | - | Up to 45 Deg. | 45-60 Deg. | Up to 45 Deg. | 45-60 Deg. | Up to 45 Deg. | 45-60 Deg. |

| Load Factor | 1 | 0.8 | 1.4 | 1 | 1.12 | 0.8 | 2.1 | 1.5 |

| Chain Dia. | Load Capacity (t) | |||||||

| 8mm | 3.0 | 2.36 | 4.25 | 3.0 | 3.35 | 2.36 | 6.3 | 4.5 |

| 10mm | 5.0 | 4.0 | 7.1 | 5.0 | 5.6 | 4.0 | 10.6 | 7.5 |

| 13mm | 8.0 | 6.3 | 11.2 | 8.0 | 9.0 | 6.3 | 17.0 | 11.8 |

| 16mm | 12.2 | 9.7 | 17.0 | 12.2 | 13.6 | 9.7 | 25.6 | 18.3 |

Characteristics

| Asymmetric Load Distribution | In this case the working load limit must be reduced by at least one chain leg, for example a 3-leg or 4-!eg sling is to be classified as a 2-leg chain sling. In case of doubt, it must be supposed that only one of the chain legs carries the entire load. | ||

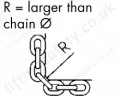

| Edge Loads |

|

|

|

| Impact Load | Slight impact | Medium impact | Strong impact |

| Load Factor | 1 | 0.7 | Impermissable |

Instructions for the safe use of chain slings

This document is issued in accordance with the requirements of Section 6 of the Health and Safety at Work etc Act 1974, amended March 1988. It outlines the care and safe use of general purpose CHAIN SLINGS and is based on Section 13 of the LEEA Code of Practice for the Safe Use of Lifting Equipment.* It should be read in conjunction with the requirements for general purpose slinging practice, given overleaf, which form an integral part of these instructions. This information is of a general nature only covering the main points for the safe use of chain slings. It may be necessary to supplement this information for specific applications.

When using chain slings always:

- Store and handle chain slings correctly.

- Inspect chain slings and accessories before use and before placing into storage.

- Follow safe slinging practices, as given overleaf.

- Fit slings carefully, protect them from sharp edges and position hooks to face outward from the load.

- Apply the correct mode factor for the slinging arrangement.

- Back hook free legs onto the master link.

When using chain slings never:

- Attempt to shorten a sling leg other than by means of an integral chain clutch.

- Force, hammer or wedge chain slings or their fittings into position.

- Lift on the point of a hook.

- Expose chain slings to chemicals, particularly acidic conditions, without consulting the supplier.

- Use chain slings at temperatures above 200°C or below minus 40°C without consulting the supplier.

- Shock load chain slings.

Selecting the Correct Sling

Chain slings are available in a range of material grades, sizes and assemblies. Select the slings to be used and plan the lift taking the following into account:

- Type of sling to be used - endless, single, two, three or four leg.

- Capacity - the sling must be both long enough and strong enough for the load and the slinging method.

- Apply the mode factor for the slinging method.

- If adjustment of the leg length is necessary select a sling with chain shortening clutches.

- For use at temperatures exceeding 200°C or below minus 40°C refer to the suppliers instructions.

- Where slings may come into contact with chemicals, particularly acids or acidic fumes, consult the supplier.**

- In the case of multi-leg slings the angle between the legs should not be less than 30° or exceed the maximum marked.

- Multi-leg slings exert a gripping force on the load which increases as the angle between the legs increases and this must be taken into account.

Storing and Handling Chain Slings

Never return damaged or contaminated slings to storage. They should be dry, clean and protected from corrosion. Store chain slings on a rack and not lying on the ground. The storage area should be dry, clean and free of any contaminates which may harm the sling. Do not alter, modify or repair a chain sling but refer such matters to a Competent Person. Never galvanise or subject a chain sling to any other plating process without the express approval of the supplier.

Using Chain Slings Safely

- Do not attempt lifting operations unless you understand the use of the equipment, the slinging procedures and the mode factors to be applied.

- Do not use defective slings or accessories.

- Do not force, hammer or wedge chain slings or fittings into position; they must fit freely. Check the correct engagement of fittings and appliances.

- Position hooks of multi-leg slings facing outward from the load. Do not lift on the point of the hook and ensure that the chain is not twisted or knotted.

- Back hook free legs to the master link to avoid lashing legs which might accidentally become engaged or otherwise become a hazard.

- Take the load steadily and avoid shock loads.

- Do not leave suspended loads unattended. In an emergency cordon off the area.

- In-service Inspection and Maintenance

- Maintenance requirements are minimal. Keep chain slings clean and protect from corrosion.

- Regularly inspect chain slings and, in the event of the following defects, refer the sling to a Competent Person for thorough examination: illegible markings; distortion of fittings; worn, stretched, bent or twisted links; ineffective safety catches; cuts, nicks, gouges, cracks, corrosion, heat discolouration or any other defect apparent to the chain or fittings.

Further information is given in: ** HSE Guidance Note PM 39 - Hydrogen Embrittlement of Grade T Chain.* The Code of Practice for the Safe Use of Lifting Equipment, published by: LEEA

GENERAL PURPOSE SLINGING PRACTICE

The following information is based on Section 1 - Appendix 1.5 of the LEEA Code of Practice for the Safe Use of Lifting Equipment.* It should be read in conjunction with the instructions for the safe use, given overleaf, of which it forms an integral part and with any specific instructions issued by the supplier. This information is of a general nature only covering the main points for the safe use of various types of slings for general lifting purposes.

ALWAYS:

- Plan the lift, establish the weight of the load and prepare the landing area ensuring that it will take the weight.

- Check slings and equipment are free of damage, use slings/slinging methods suitable for the load and protect slings from sharp edges and corners.

- Attach the sling securely to the load and appliance and position hooks to face outwards.

- Ensure the load is balanced and will not tilt or fall.

- Keep fingers, toes etc clear when tensioning slings and when landing loads.

- Ensure that the load is free to be lifted.

- Make a trial lift and trial lower.

NEVER:

- Use damaged slings or accessories.

- Twist, knot or tie slings.

- Hammer slings into position.

- Overload slings due to the weight of the load or the mode of use.

- Trap slings when landing the load.

- Drag slings over floors etc or attempt to pull trapped slings from under loads.

- Allow personnel to ride on loads.

Sling Configurations and Rating

Slings are available in single, two, three and four leg or endless form. In practice it will be found that chain, wire rope and fibre rope slings are available in any of these configurations but that flat woven webbing is limited to single leg and endless whilst roundslings are only supplied in endless form. The maximum load that a sling may lift in use will be governed by the slinging arrangement (mode of use) and may vary from the marked SWL.** In the case of textile slings the SWL for the various modes of use is usually given on the information label. In other cases it is necessary to multiply the marked SWL by a mode factor.***

The following three simple rules will ensure that the sling is not overloaded. In some cases this will mean that the sling will be under utilised although this is unlikely to hinder the user unduly. Where the maximum utilisation is required reference should be made to a Competent Person who understands the factors involved and who can perform the necessary calculations. (1) For straight lift never exceed the marked SWL and in the case of multi-leg slings the specified angle or range of angles. (2) When using slings in choke hitch multiply the marked SWL by 0.8 to obtain the reduced maximum load the sling may lift ie reduce the safe working load by 20%. (3) With multi-leg slings, when using less than the full number of legs, reduce the maximum load in proportion to the number of legs in use. Simply multiply the marked SWL by the number of legs in use expressed as a fraction of the total thus: one leg of a two leg sling = ½ marked SWL, three legs of a four leg sling = ¾ marked SWL and so on.

Operative Training

Slings should only be used by trained operatives who understand the methods of rating and application of mode factors.**** Safe use of Slings

- Good slinging practice must ensure that the load is as safe and secure in the air as it was on the ground and that no harm is done to the load, lifting equipment, other property or persons.

- Establish the weight of the load, ensure the lifting method is suitable and inspect the sling and attachments for obvious defects. Prepare the landing area making sure the floor is strong enough to take the load. Follow any specific instructions from the supplier.

- Ensure the lifting point is over the centre of gravity. Any loose parts of the load should be removed or secured. Secure the sling firmly to the load by hooks onto lifting points or shackles etc. The sling must not be twisted, knotted or kinked in any way.

- Use packing to prevent damage to the sling from corners or edges and to protect the load.

- Do not exceed the SWL or rated angle. Any choke angle must not exceed 120° and any basket 90°.

- Do not hammer, force or wedge slings or accessories into position; they must fit freely.

- When attaching more than one sling to the hook of the appliance use a shackle to join the slings and avoid overcrowding the hook.

- Use an established code of signals to instruct the crane driver.

- Ensure the load is free to be lifted and not, for example, bolted down.

- Check that there are no overhead obstacles such as power lines.

- Keep fingers, toes etc clear ensuring they do not become trapped when lifting, lowering or controlling loads.

- Make a trial lift by raising the load a little to ensure it is balanced, stable and secure and if not lower it and adjust the slinging arrangement.

- Where appropriate use tag lines to control the load.

- Except where special provision is made, do not allow anyone to pass under or ride upon the load. The area should be kept clear.

- Make a trial set down, ensure the sling will not become trapped and the load will not tip when the slings are released. Use supports which are strong enough to sustain the load without crushing.

- Never drag slings over floors etc or attempt to drag a trapped sling from under a load.

- Never use a sling to drag a load.

- Place the hooks of free legs back onto the master link and take care to ensure that empty hooks do not become accidentally engaged.

- Never use slings in contact with chemicals or heat without the manufacturers approval.

- Never use damaged or contaminated slings.

- On completion of the lift return all equipment to proper storage.

|

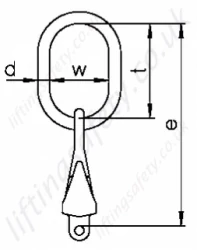

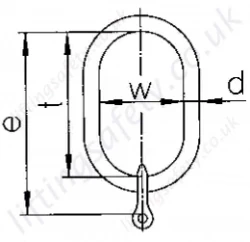

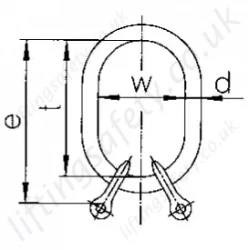

Grade 12 / 120 - 1 Leg Sub Assembly with Shortening Device

|

|||||||||||||||||||||||||||||||||||||||||||||

|

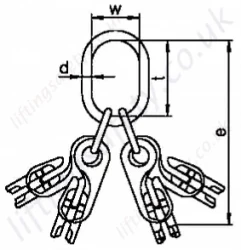

Grade 12 / 120 - 2 Leg Sub Assembly with Shortening Devices

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - 3 and 4 Leg Sub Assembly with Shortening Devices

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - 1 Leg Sub Assembly

|

|||||||||||||||||||||||||||||||||||||||||||||

|

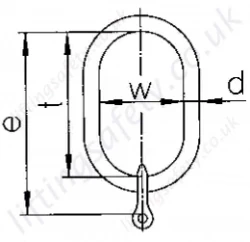

Grade 12 / 120 - 2 Leg Sub Assembly

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - 3 and 4 Leg Sub Assembly

|

|||||||||||||||||||||||||||||||||||||||||||||

|

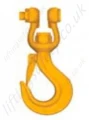

Grade 12 / 120 - Clevis Sling Hook

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - Clevis Self Locking Hook

|

Pricing

Grade 12 / 120 Lifting chain sling assemblies. Manufactured in Austria, and tailored to meet the growing global demand for top-quality lifting equipment.

Single Leg Chains, 2 Leg Chains, 3 Leg and 4 Leg Chain slings at any length to suit your application with an optional in-line shortening clutch fitted for leg length adjustment.

As well as grade 12 chain slings, we also offer grade 8, grade 10, grade 6 stainless steel or even dyneema (synthetic) chain sling variants that in some instances can be more cost-effective or beneficial due to other features or requirements - harsher environments for example.

Advantages

- High wear resistance due to increased hardness.

- Traceability: appropriate marking on chains & components.

- 50% higher load capacity compared to Grade 8/80.

- 20% higher load capacity compared to Grade 10/100.

- Safety factor 4:1.

- Use of high-grade steels and alloys.

- Production on specially developed bending and welding machines in Europe.

- Process controlled heat and surface procedures.

- BG approved – H29 Number.

- Continuous quality control (ISO 9001, 9002) ongoing research and development of the product.

- Temperature range: -40° to 200°C

Load Chart

| Number of Legs | 1 Leg | 1 Leg | 2 Leg | 2 Leg | 3 and 4 Leg | |||

| Image Example |

|

|

|

|

|

|||

| Angle of Inclination | - | - | Up to 45 Deg. | 45-60 Deg. | Up to 45 Deg. | 45-60 Deg. | Up to 45 Deg. | 45-60 Deg. |

| Load Factor | 1 | 0.8 | 1.4 | 1 | 1.12 | 0.8 | 2.1 | 1.5 |

| Chain Dia. | Load Capacity (t) | |||||||

| 8mm | 3.0 | 2.36 | 4.25 | 3.0 | 3.35 | 2.36 | 6.3 | 4.5 |

| 10mm | 5.0 | 4.0 | 7.1 | 5.0 | 5.6 | 4.0 | 10.6 | 7.5 |

| 13mm | 8.0 | 6.3 | 11.2 | 8.0 | 9.0 | 6.3 | 17.0 | 11.8 |

| 16mm | 12.2 | 9.7 | 17.0 | 12.2 | 13.6 | 9.7 | 25.6 | 18.3 |

Characteristics

| Asymmetric Load Distribution | In this case the working load limit must be reduced by at least one chain leg, for example a 3-leg or 4-!eg sling is to be classified as a 2-leg chain sling. In case of doubt, it must be supposed that only one of the chain legs carries the entire load. | ||

| Edge Loads |

|

|

|

| Impact Load | Slight impact | Medium impact | Strong impact |

| Load Factor | 1 | 0.7 | Impermissable |

Instructions for the safe use of chain slings

This document is issued in accordance with the requirements of Section 6 of the Health and Safety at Work etc Act 1974, amended March 1988. It outlines the care and safe use of general purpose CHAIN SLINGS and is based on Section 13 of the LEEA Code of Practice for the Safe Use of Lifting Equipment.* It should be read in conjunction with the requirements for general purpose slinging practice, given overleaf, which form an integral part of these instructions. This information is of a general nature only covering the main points for the safe use of chain slings. It may be necessary to supplement this information for specific applications.

When using chain slings always:

- Store and handle chain slings correctly.

- Inspect chain slings and accessories before use and before placing into storage.

- Follow safe slinging practices, as given overleaf.

- Fit slings carefully, protect them from sharp edges and position hooks to face outward from the load.

- Apply the correct mode factor for the slinging arrangement.

- Back hook free legs onto the master link.

When using chain slings never:

- Attempt to shorten a sling leg other than by means of an integral chain clutch.

- Force, hammer or wedge chain slings or their fittings into position.

- Lift on the point of a hook.

- Expose chain slings to chemicals, particularly acidic conditions, without consulting the supplier.

- Use chain slings at temperatures above 200°C or below minus 40°C without consulting the supplier.

- Shock load chain slings.

Selecting the Correct Sling

Chain slings are available in a range of material grades, sizes and assemblies. Select the slings to be used and plan the lift taking the following into account:

- Type of sling to be used - endless, single, two, three or four leg.

- Capacity - the sling must be both long enough and strong enough for the load and the slinging method.

- Apply the mode factor for the slinging method.

- If adjustment of the leg length is necessary select a sling with chain shortening clutches.

- For use at temperatures exceeding 200°C or below minus 40°C refer to the suppliers instructions.

- Where slings may come into contact with chemicals, particularly acids or acidic fumes, consult the supplier.**

- In the case of multi-leg slings the angle between the legs should not be less than 30° or exceed the maximum marked.

- Multi-leg slings exert a gripping force on the load which increases as the angle between the legs increases and this must be taken into account.

Storing and Handling Chain Slings

Never return damaged or contaminated slings to storage. They should be dry, clean and protected from corrosion. Store chain slings on a rack and not lying on the ground. The storage area should be dry, clean and free of any contaminates which may harm the sling. Do not alter, modify or repair a chain sling but refer such matters to a Competent Person. Never galvanise or subject a chain sling to any other plating process without the express approval of the supplier.

Using Chain Slings Safely

- Do not attempt lifting operations unless you understand the use of the equipment, the slinging procedures and the mode factors to be applied.

- Do not use defective slings or accessories.

- Do not force, hammer or wedge chain slings or fittings into position; they must fit freely. Check the correct engagement of fittings and appliances.

- Position hooks of multi-leg slings facing outward from the load. Do not lift on the point of the hook and ensure that the chain is not twisted or knotted.

- Back hook free legs to the master link to avoid lashing legs which might accidentally become engaged or otherwise become a hazard.

- Take the load steadily and avoid shock loads.

- Do not leave suspended loads unattended. In an emergency cordon off the area.

- In-service Inspection and Maintenance

- Maintenance requirements are minimal. Keep chain slings clean and protect from corrosion.

- Regularly inspect chain slings and, in the event of the following defects, refer the sling to a Competent Person for thorough examination: illegible markings; distortion of fittings; worn, stretched, bent or twisted links; ineffective safety catches; cuts, nicks, gouges, cracks, corrosion, heat discolouration or any other defect apparent to the chain or fittings.

Further information is given in: ** HSE Guidance Note PM 39 - Hydrogen Embrittlement of Grade T Chain.* The Code of Practice for the Safe Use of Lifting Equipment, published by: LEEA

GENERAL PURPOSE SLINGING PRACTICE

The following information is based on Section 1 - Appendix 1.5 of the LEEA Code of Practice for the Safe Use of Lifting Equipment.* It should be read in conjunction with the instructions for the safe use, given overleaf, of which it forms an integral part and with any specific instructions issued by the supplier. This information is of a general nature only covering the main points for the safe use of various types of slings for general lifting purposes.

ALWAYS:

- Plan the lift, establish the weight of the load and prepare the landing area ensuring that it will take the weight.

- Check slings and equipment are free of damage, use slings/slinging methods suitable for the load and protect slings from sharp edges and corners.

- Attach the sling securely to the load and appliance and position hooks to face outwards.

- Ensure the load is balanced and will not tilt or fall.

- Keep fingers, toes etc clear when tensioning slings and when landing loads.

- Ensure that the load is free to be lifted.

- Make a trial lift and trial lower.

NEVER:

- Use damaged slings or accessories.

- Twist, knot or tie slings.

- Hammer slings into position.

- Overload slings due to the weight of the load or the mode of use.

- Trap slings when landing the load.

- Drag slings over floors etc or attempt to pull trapped slings from under loads.

- Allow personnel to ride on loads.

Sling Configurations and Rating

Slings are available in single, two, three and four leg or endless form. In practice it will be found that chain, wire rope and fibre rope slings are available in any of these configurations but that flat woven webbing is limited to single leg and endless whilst roundslings are only supplied in endless form. The maximum load that a sling may lift in use will be governed by the slinging arrangement (mode of use) and may vary from the marked SWL.** In the case of textile slings the SWL for the various modes of use is usually given on the information label. In other cases it is necessary to multiply the marked SWL by a mode factor.***

The following three simple rules will ensure that the sling is not overloaded. In some cases this will mean that the sling will be under utilised although this is unlikely to hinder the user unduly. Where the maximum utilisation is required reference should be made to a Competent Person who understands the factors involved and who can perform the necessary calculations. (1) For straight lift never exceed the marked SWL and in the case of multi-leg slings the specified angle or range of angles. (2) When using slings in choke hitch multiply the marked SWL by 0.8 to obtain the reduced maximum load the sling may lift ie reduce the safe working load by 20%. (3) With multi-leg slings, when using less than the full number of legs, reduce the maximum load in proportion to the number of legs in use. Simply multiply the marked SWL by the number of legs in use expressed as a fraction of the total thus: one leg of a two leg sling = ½ marked SWL, three legs of a four leg sling = ¾ marked SWL and so on.

Operative Training

Slings should only be used by trained operatives who understand the methods of rating and application of mode factors.**** Safe use of Slings

- Good slinging practice must ensure that the load is as safe and secure in the air as it was on the ground and that no harm is done to the load, lifting equipment, other property or persons.

- Establish the weight of the load, ensure the lifting method is suitable and inspect the sling and attachments for obvious defects. Prepare the landing area making sure the floor is strong enough to take the load. Follow any specific instructions from the supplier.

- Ensure the lifting point is over the centre of gravity. Any loose parts of the load should be removed or secured. Secure the sling firmly to the load by hooks onto lifting points or shackles etc. The sling must not be twisted, knotted or kinked in any way.

- Use packing to prevent damage to the sling from corners or edges and to protect the load.

- Do not exceed the SWL or rated angle. Any choke angle must not exceed 120° and any basket 90°.

- Do not hammer, force or wedge slings or accessories into position; they must fit freely.

- When attaching more than one sling to the hook of the appliance use a shackle to join the slings and avoid overcrowding the hook.

- Use an established code of signals to instruct the crane driver.

- Ensure the load is free to be lifted and not, for example, bolted down.

- Check that there are no overhead obstacles such as power lines.

- Keep fingers, toes etc clear ensuring they do not become trapped when lifting, lowering or controlling loads.

- Make a trial lift by raising the load a little to ensure it is balanced, stable and secure and if not lower it and adjust the slinging arrangement.

- Where appropriate use tag lines to control the load.

- Except where special provision is made, do not allow anyone to pass under or ride upon the load. The area should be kept clear.

- Make a trial set down, ensure the sling will not become trapped and the load will not tip when the slings are released. Use supports which are strong enough to sustain the load without crushing.

- Never drag slings over floors etc or attempt to drag a trapped sling from under a load.

- Never use a sling to drag a load.

- Place the hooks of free legs back onto the master link and take care to ensure that empty hooks do not become accidentally engaged.

- Never use slings in contact with chemicals or heat without the manufacturers approval.

- Never use damaged or contaminated slings.

- On completion of the lift return all equipment to proper storage.

|

Grade 12 / 120 - 1 Leg Sub Assembly with Shortening Device

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - 2 Leg Sub Assembly with Shortening Devices

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - 3 and 4 Leg Sub Assembly with Shortening Devices

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - 1 Leg Sub Assembly

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - 2 Leg Sub Assembly

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - 3 and 4 Leg Sub Assembly

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - Clevis Sling Hook

|

|||||||||||||||||||||||||||||||||||||||||||||

|

Grade 12 / 120 - Clevis Self Locking Hook

|

Products of Possible Interest

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.